|

Visit our website at

www.customspinnerets.com

|

| Eight Amazing Applications for Coaxial Electrospinning |

|

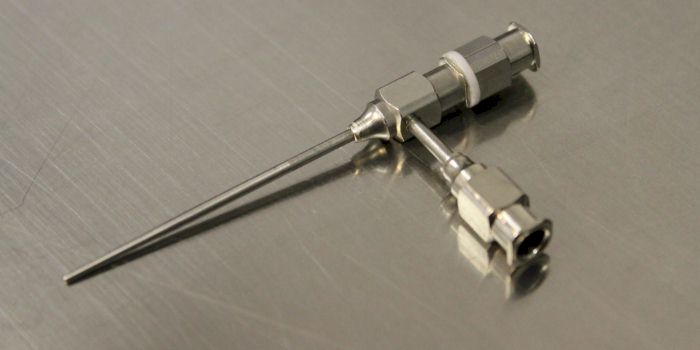

This month we share with you (8)

applications for coaxial electrospinning that are helping make the world

a better place. Each of these methods was developed using a coaxial

spinneret made by ramé-hart instrument co.

1. There is nothing more annoying than being in the jungle and then having mosquitoes nip at your neck all day and night. Researchers at the Naval Research Lab in Washington DC have developed a method for producing coaxial electrospun fibers made from Nylon 6/6 with a tunable time release core of the insect repellent Picaridin.1 This development has the potential to provide insect repellency to military gear over its lifetime with the capacity to withstand high-temperature machine drying. 2. Encapsulating living stem cells in a hydrogel sheath using coaxial electrospraying is a novel technique developed at Ohio State.2 The proposed technology promises a method for developing and delivering medicine for treating organ impairments through tissue regeneration. What makes this solution potentially powerful is the freedom that this method offers for fine-tuning the size and properties of the microcapsules and the density of the encapsulated stem cells. This gives microtissue engineering another tool for solving complex healing solutions. 3. Researchers in Spain and at the University of Delaware have been working separately on developing biodegradable nanofibers using both coaxial and triaxial electrospinning techniques.3 One potential solution is to load two different drugs in different layers of polycaproactone (PCL), each with its own release profile. Both coaxial and triaxial nanofibers were produced and demonstrated that novel methods could facilitate the production of biomolecular delivery vehicles for tissue engineering applications. 4. Thermochromic material can absorb heat which results in a chemical reaction that causes the material to change color. Researchers at Virginia Commonwealth University have developed methods for producing coaxial electrospun thermochromic fibers that are embedded with liquid crystal formulations.4 This proof-of-concept study opens the door to myriad potential temperature-indicating applications that could benefit from coaxial-spun fibers with thermochromic behavior.

5. Coaxial nickel ferrite-barium titanate core-shell nanofibers were produced via coaxial electrospinning by researchers at Oakland University and elsewhere.5 Superstructures made up of these fibers have potential application as magnetic sensors in high frequency devices. These nanofibers have high surface-to-volume ratios which result in strong magneto-electric coupling. Potential uses include medical devices, microwave absorbers, magnet-optical devices, and information and data storage. 6. Researchers at Calstate have made red light-emitting nanofibers by way of a process called electrohydrodynamic co-casting.6 By selectively controlling the proportions of base materials, a variety of red light-emitting behavior, magnetic responsiveness, and fluorescence was observed. Potential applications include chemical sensing, photoluminescence, fuorescence, biomarking, and photon sensing. 7. Brazilian scientists have fabricated coaxial nanofibers using hydrophobic polymers such as PMMA (polymethyl methacrylate) and PCL (polycaprolactone).7 The fiber was also loaded with Nimesulide, an anti-inflammatory drug. By controlling production variables and material quantities, thermal, mechanical, and wetting properties could be optimized. By loading the drug in the sheath (instead of the core), faster release rates can be obtained. 8. A graduate student at Cornell proposed using coaxially electrospun polymeric sulfur or poly(S-r-DIB) copolymer nanofibers in the fabrication of lithium-sulfer battery cathodes in an effort to reduce volume expansion and improve capacity retention.8 A combination of low materials price and potentially high energy densities, the lithium-sulfer battery design is a compelling candidate for many rechargeable battery applications. If you have an application that you'd like to share, please contact us and we'll consider including it in a future edition of this newsletter. If you're looking to do coaxial electrospinning, check out our array of spinneret products at our website. 1 See NRL Public Report

here. |

| Coupon Savings |

|

Here are some ways to save on your

next spinneret order: 1. Order any spinneret, prebuilt or custom, and get $30 off your order. Simply use coupon code SAVE30 during checkout at http://www.ramehart.us/coaxial-needles/. Limit one use per customer. Cannot be combined with other offers. Valid until 1-Jun-2021. 2. Order any three or more spinnerets, prebuilt or custom, and get a $100 off your order. Use coupon code SAVE100 during checkout at http://www.ramehart.us/coaxial-needles/. Limit one use per customer. Cannot be combined with other offers. Valid until 1-Jun-2021.

|

|

Regards,

Carl Clegg |