|

February

2026 |

| How Surface Science is Reinventing the Frying Pan |

|

Surface science has led to many technological developments that have improved the lives of billions. In the past, the notion that the advancement of science and technology is beneficial to the world was widely accepted. In the last two decades, however, some advances have been scrutinized by the public. Headlines increasingly highlight cases where familiar materials or products—once symbols of modern convenience—are reexamined for potential environmental, health, or safety risks. Nonstick cookware is one such example. The first nonstick pans were introduced to the market in the 1950’s. Intended to replace the need for using cooking oils, these metal pans had a bonded polytetrafluoroethylene (PTFE) coating that formed a low adhesion interface. The product was a hit with consumers. Over time, the coatings were refined to improve durability and scratch resistance and were widely adopted.

In the early 2000’s, concerns were raised that PTFE could potentially produce toxic fumes if heated to high temperatures1. Public attention intensified in 2018 when a Washington Post article on perfluoroalkyl substances (PFAS)2 popularized the term “forever chemicals,” highlighting their persistence in the environment. Subsequent films and media coverage linked PFAS to PTFE manufacturing, renewing fears about the safety of PTFE cookware. However, recent evidence3 suggests there is little risk of adverse health effects to humans from normal use of PTFE non-stick coatings (birds, on the other hand, face some risks from fume toxicity). PTFE manufacturing has transitioned away from the use of perfluorooctanoic acid (PFOA), a PFAS known to be toxic and environmentally problematic, to newer materials. The impacts of these new materials are still being investigated. While occupational exposure and effects on health and the environment are still being studied, many consumers have opted for alternatives that avoid PTFE entirely. The primary non-PTFE coating, which typically uses sol-gel technology to create a silica-based film on the surface of the pan, is known as a ceramic coating. Ceramic coatings have higher adhesion than PTFE and are more brittle, but they do have a number of advantages4:

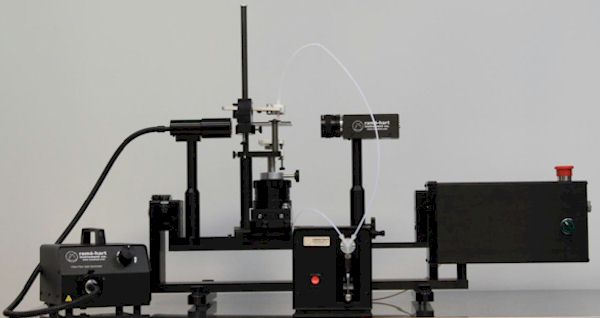

As the public’s perception of nonstick coatings evolves, surface science remains essential for separating perception from measurable performance. Contact angle goniometry is a key tool for understanding the performance of all varieties of nonstick cookware. Equilibrium contact angle and surface energy can provide insight into the innate adhesive properties of a coating material. Contact angle hysteresis and roll-off angle can reveal important information about surface topography, pinning characteristics, and real-world nonstick performance. ramé-hart instrument company offers a variety of instruments and accessories that are essential for studying the nonstick materials. Our line of goniometers are robust tools for high precision contact angle measurements. Accessories like the Advanced Chamber, Hot Plate, and Heated Environmental Cell enable advanced characterization under controlled thermal and environmental conditions. The Automated Tilting Base is essential for determining advancing and receding contact angles, contact angle hysteresis, and roll-off angle.

Notes |

| Product of the Month: ramé-hart Automated Tilting Base |

|

Many surface

scientists are interested in studying

advancing and receding contact

angles,

contact angle hysteresis,

and

roll-off angle. These

metrics provide more valuable information than a simple equilibrium

contact angle about the wetting properties of a surface. The

Automated Tilting Base

(p/n 100-25-A) is one of the most popular accessories. The Automated

Tilting Base is precisely controlled with a precision stepper motor and

is fully software-controlled by ramé-hart DROPimage Advanced software

for automated methods-based experiments and precision contact angle

measurements at any angle.

The Automated Tilting Base is included with both Model 290 and Model 590 and can be ordered with any instrument that ships with DROPimage Advanced. For more information about the Automated Tilting Base and a product brochure, visit the product page here. For a quote or information about our other instruments and accessories, please contact us. |

|

Regards,

Carl Clegg |