|

September 2010 |

|

| Roughness and Contact Angle | |

|

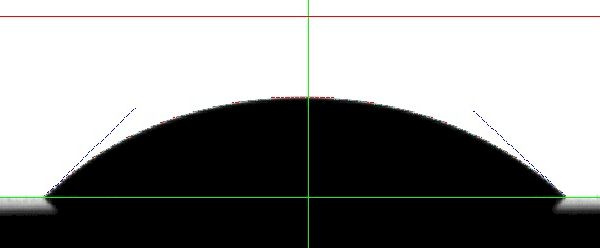

The effect of roughness on contact angle can be confusing and is often misunderstood. Our purpose herein will be to clarify the impact roughness has on contact angle for various types of surfaces. We will begin with the assumption that increased roughness will decrease the contact angle. To test this premise, we started with a virgin sample of nylon. The nylon we used is the most common variety, type 6/6. It's called 6/6 because in this copolymoer, diamine and diacid each donate 6 carbons to the polymer chain. We then cleaned the sample with IPA and dispensed 6µL of pure deionized water on the untreated (glossy) surface and measured the resulting contact angle which averaged 57.2° as shown below.

Next, we used a virgin sheet of 320 grit aluminum oxide sandpaper affixed to a random orbital sander (to prevent directional graining) and roughened the surface of the same 6/6 nylon by sanding for approximately 1 minute. We then cleaned the sample with IPA and measured the contact angle. The abraded sample contact angle averaged 45.9° as shown below.

Here we have proved that increased roughness will lower the measured contact angle. This phenomenon can be explained by Wenzel's equation: cos θ* = r cos θ where θ* refers to the apparent (rough surface) contact angle, θ refers to the Young contact angle (on ideal smooth surface) and r refers to the roughness ratio (which is 1.0 for an ideal smooth surface). In the example above, we calculate a roughness ratio (r) of 1.285 for the abraded sample. Next we moved to a solid untreated piece of PTFE (polytetrafluoroethylene). We used a certified sample of Texolon® Brand High Performance Premium Virgin PTFE 8764 which is the highest grade available. On the untreated sample, we measured a water contact angle of 108.6° as shown below.

We then abraded the surface using the same technique described above for the nylon sample and measured again. The contact angle increased from 108.6° to 121.0° as shown below. The calculated roughness ratio r for this sample is 1.6149 which is higher than the nylon but expected due to the differences in hardness, abrasion resistance, and other mechanical properties.

This behavior is contrary to our original premise that increased roughness will decrease the contact angle. According to Wenzel's equation, roughness will decrease the contact angle when the apparent contact angle is under 90° but will increase the contact angle when the apparent contact angle is over 90°. Thus, we can say that increased roughness will decrease the measured contact angle on hydrophilic surfaces but increase the measured contact angle on hydrophobic surfaces as we've proved with our nylon and PTFE measurements. We could also say that increased roughness amplifies both hydrophilicity and hydrophobicity (but not necessarily linearly).

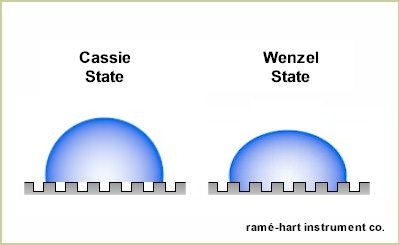

But even this is not always true. It's only true with the drop is sitting on the surface with no air voids underneath - that is to say, in a Wenzel State. When the drop is suspended on asperities with air in the voids underneath - that is, in a Cassie state - then a different set of equations are used to define this condition. Plants use roughness in a Cassie state to increase hydrophobicity and even to make their surfaces ultrahydrophobic while the underlying materials are hydrophilic. In a similar manner, researchers are using hydrophilic materials such as silica to fabricate ultrahydrophobic engineered surfaces that rely on texturing (orderly roughness) at the micro and nanoscale. For a complete review or Cassie and Wenzel, see our September 2008 Newsletter. While Wenzel's equation can be used to describe the change in contact angle as a function of roughness, it does not describe contact angle hysteresis. An increase in roughness can increase contact angle hysteresis but so too can chemical heterogeneity and contamination. As we increase the roughness of a surface, the contact angle in a Wenzel state will generally increase on hydrophobic surface and decrease on hydrophilic surfaces - but increased roughness will increase the contact angle hysteresis at least when the drop is in a Wenzel state. In a Cassie state, by contrast, contact angle hysteresis is driven more by the solid fraction (the amount of solid that is in contact with the drop) and not surface roughness. For more discussion on contact angle hysteresis, see our February 2008 and July 2010 Newsletters. The measurements taken on nylon and PTFE as described above can be done on any ramé-hart contact angle goniometer - including our newly redesigned entry-level Model 190. For more advanced studies including advancing and receding contact angle with our Automated Tilting Base, consider our Automated Model 290 or Model 590. |

|

|

|