|

Visit our website at

www.customspinnerets.com

|

|

Gas-Assisted Electrospinning |

|

Gas-assisted electrospinning is a popular variation of traditional electrospinning that has some unique advantages. In this newsletter we will discuss some of the reasons someone might want to flow gas coaxially and some of the options ramé-hart offers for gas-assist applications. One of the most common challenges with electrospinning is instability in the Taylor cone. This can lead to interrupted jet formation and inconsistent fiber deposition. In some cases, this issue can be addressed by adjustments to settings or instrumentation, but some of the root causes may be factors beyond your control. Coaxial gas flow can improve Taylor cone stability by introducing a controlled, directional momentum field around the cone1. This acts as a buffer for the competition between the electric field pulling the liquid away from the needle and the surface tension pulling inward. The gas also forms a sheath that protects from perturbations from air currents or humidity. Finally, gas flow prevents any buildup on the tip of the needle, which can disrupt cone formation. Coaxial gas flow can also improve fiber deposition. As material exits the needle and passes from the Taylor cone to the jet, it whips chaotically as it passes through the electric field. Although this whipping is necessary to produce nanofibers, it also makes it very difficult to control where the fibers land on a collector. Inconsistent deposition leads to non-uniform layering and thickness. Coaxial gas can give the jet momentum in the correct direction and briefly delay the onset of whipping, which effectively narrows the window where the fiber may land1. Finally, gas flow can resolve evaporation issues, whether the solvent is evaporating too slowly or too quickly. When the evaporation rate is too slow, the fiber will land on the collector before it has fully solidified. This can impact the structure of the mat and cause it to stick to the collector. Slow evaporation can also promote the collection of material on the needle tip. Flowing a dry gas can increase the rate of evaporation and mitigate this problem2. Alternatively, evaporation may occur too quickly. When evaporation is too fast, it may lead to premature jet solidification or result in porous fibers. Evaporation can be slowed by flowing a gas saturated in the solvent. ramé-hart offers a number of options that can enable coaxial gas flow. First, coaxial gas flow requires a coaxial needle at a minimum. Some applications require a triaxial or quadaxial needle. Our needles are expertly formed and centered to ensure even flow. We can also create spinnerets where the inner needle is longer or shorter than the outer needle, which is important for some gas applications (see DIM C on our coaxial spinneret drawing). Second, inlets for our spinnerets can be made fit a Luer adapter, or with push-to-connect tubing adapters. These can be found on Box 3 of our coaxial spinnerets page. Third, we offer a PTFE or FEP Tubing Kit that can extend the fluid path to the inlet. Finally, our Electrospinning Check Tool can help you to quickly determine whether your process is running properly.

Whether you are looking for high-quality coaxial needles for gas-assisted electrospinning or any other application, contact us to learn more about our products. Notes 1 Zhang, R., Chen, X., Wang, H., Sun, J., Huang, S., Zhang, X., & Long, J. (2025). Study on Deposition of Coaxial Electrospinning Fibers by Coaxial Auxiliary Flow Field. Polymers, 17(3), 396. https://doi.org/10.3390/polym17030396 2 Xu, G., Chen, M., Gao, Y., Chen, Y., Luo, Z., Wang, H., ... & Chen, R. (2023). Gas-assisted electrospinning of high-performance ceramic fibers: Optimal design modeling and experimental results of the gas channel of the nozzle. Frontiers in Materials, 10, 1113168. https://doi.org/10.3389/fmats.2023.1113168 |

|

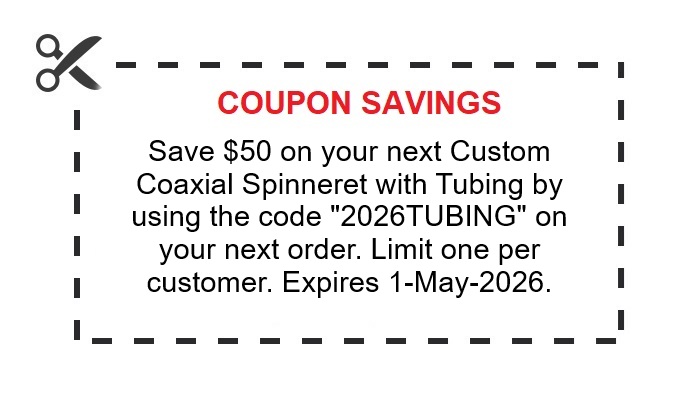

Coupon Savings

|

|

|

|

Thank you for your continued business. Regards,

Carl Clegg |